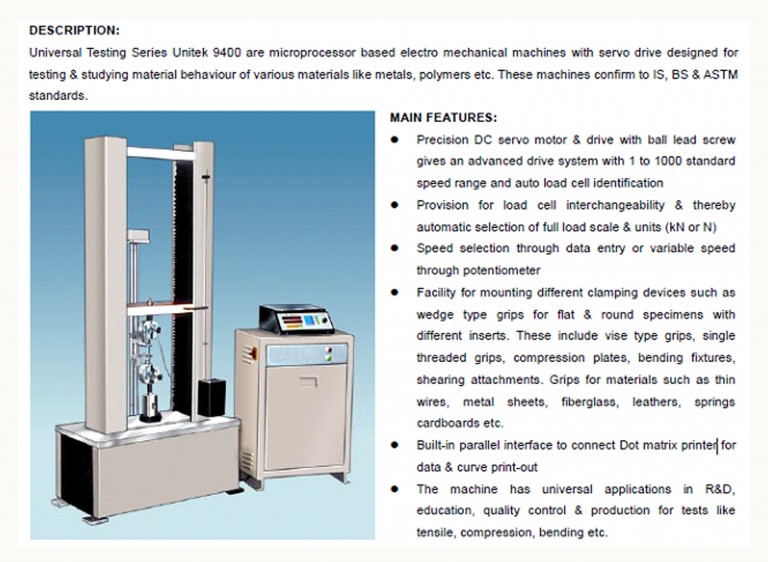

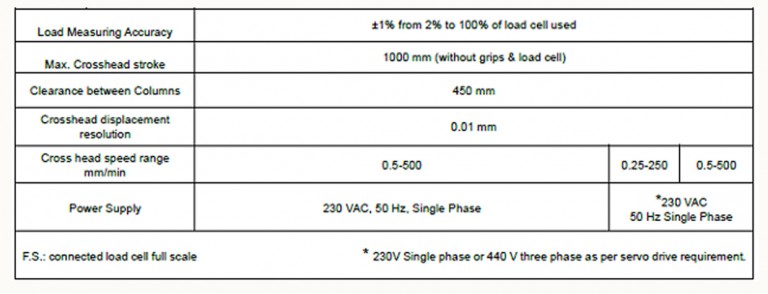

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS

SPECIFICATIONS

FEATURES

FEATURES

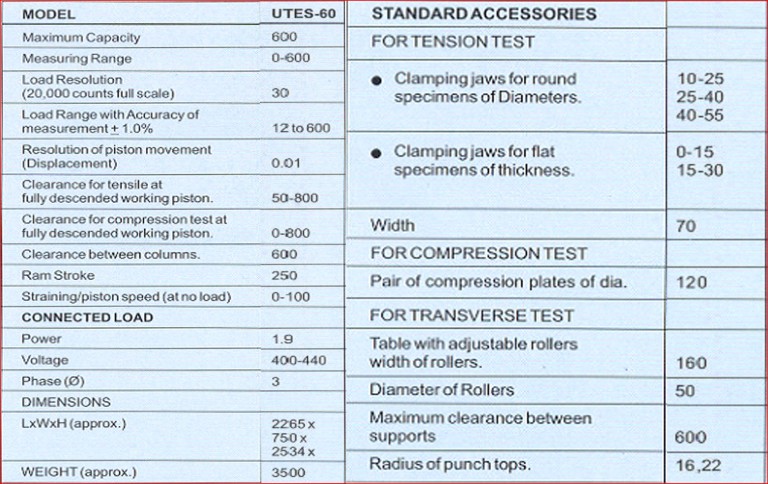

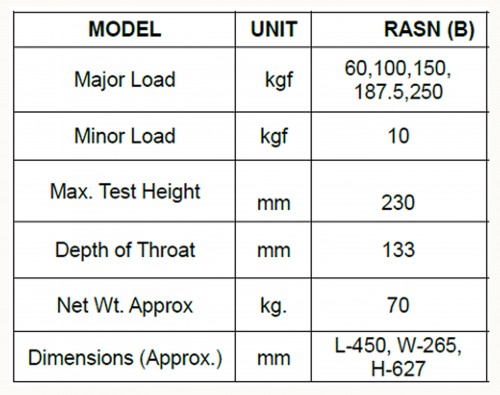

HARDNESS TESTING MACHINE

HARDNESS TESTING MACHINE

The new 'RASN B' series of Hardness Testing Machines come with much improved design & look with ROCKWELL CUM BRINNEL .

1) The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated to improve aesthetic appeal and durability since the paint does not fade giving a fresh look to the machine over a long period.

2) The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.5 mm when raised to full height. The accuracy is returned for years together due to hardened bush.

3) A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantee no change in results due to rough handling of test table or test piece resulting in trouble free maintenance and life long accuracy.

4) A antifriction linear bearing with almost no clearance provided for a perfect vertical movement of loading plunger with minimum friction. This enables testing small dia. pin or ball upto 3mm dia.

5) All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting is avoided.

6) All four modules confirm to respective standards as

IS : 3804, BS 10109-2 & ASTME-18 for Rockwell Test. IS : 5073, BS 10189-2 & ASTME-18 for Rockwell Superficial IS : 2281, BS 1003-2 & ASTME-10 for Brinell Test. SPECIFICATIONS FOR HARDNESS MACHINE Specification for Hardness Machine IMPACT TESTING MACHINE

IMPACT TESTING MACHINE

Impact Testing MachineThe pendulum Impact Tester, Model: BS-IT 30 is designed for conducting Izod, Charpy test. The test methods confirm to BS:131:PART 4-1972 (Amended 15 Aug. 1993) BSEN : 10045-2 :1993. The pendulum is mounted on antifriction bearings. It has two starting positions, the upper one for Charpy & the lower one for Izod testing. On release the Pendulum swings down to break the specimen and the energy absorbed in doing so is measured as the difference between the height of drop before rupture and the of rise after rupture of the test specimen and is read from the maximum pointer position on the dial scale. (It is read on digital readout in case of electronic machines.) There are two strikers and one support anvil available for fitting in to the pendulum and on the base of the machine for the Izod,Charpy test respectively. Changing from one striker to another is achieved simply by fixing the new striker into it's position.